100x50x50 cm Wire Cages Welded Mesh Gabion Walls

- Place of Origin:

-

Hebei, China

- Brand Name:

-

Sinodiamond

- Model Number:

-

JS-019

- Material:

-

Galvanized Iron Wire, Galvanized Iron Wire

- Type:

-

Welded Mesh

- Application:

-

Gabions

- Hole Shape:

-

Square

- Aperture:

-

50*50mm, 100*100mm

- Wire Gauge:

-

2.0-4.0 mm

- Surface treatment:

-

Galvanised

- Packaging:

-

compaction and bundle or in pallet

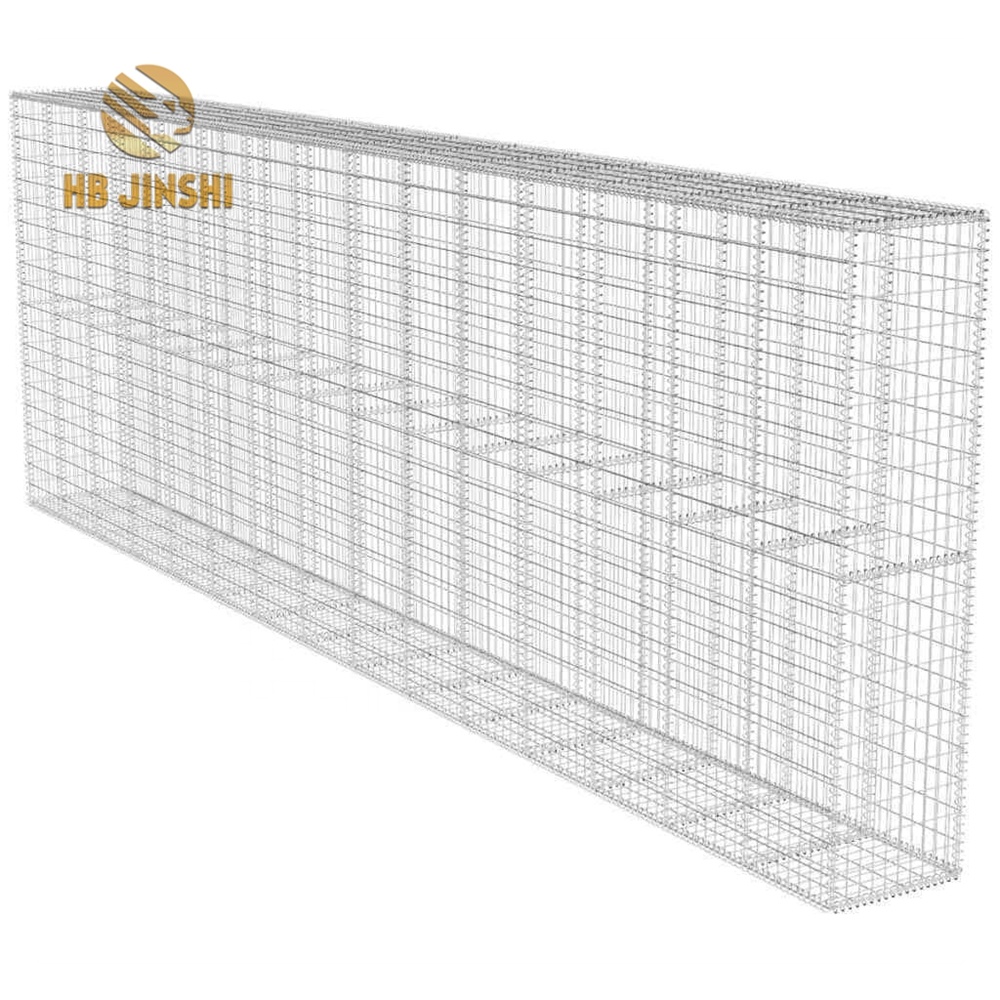

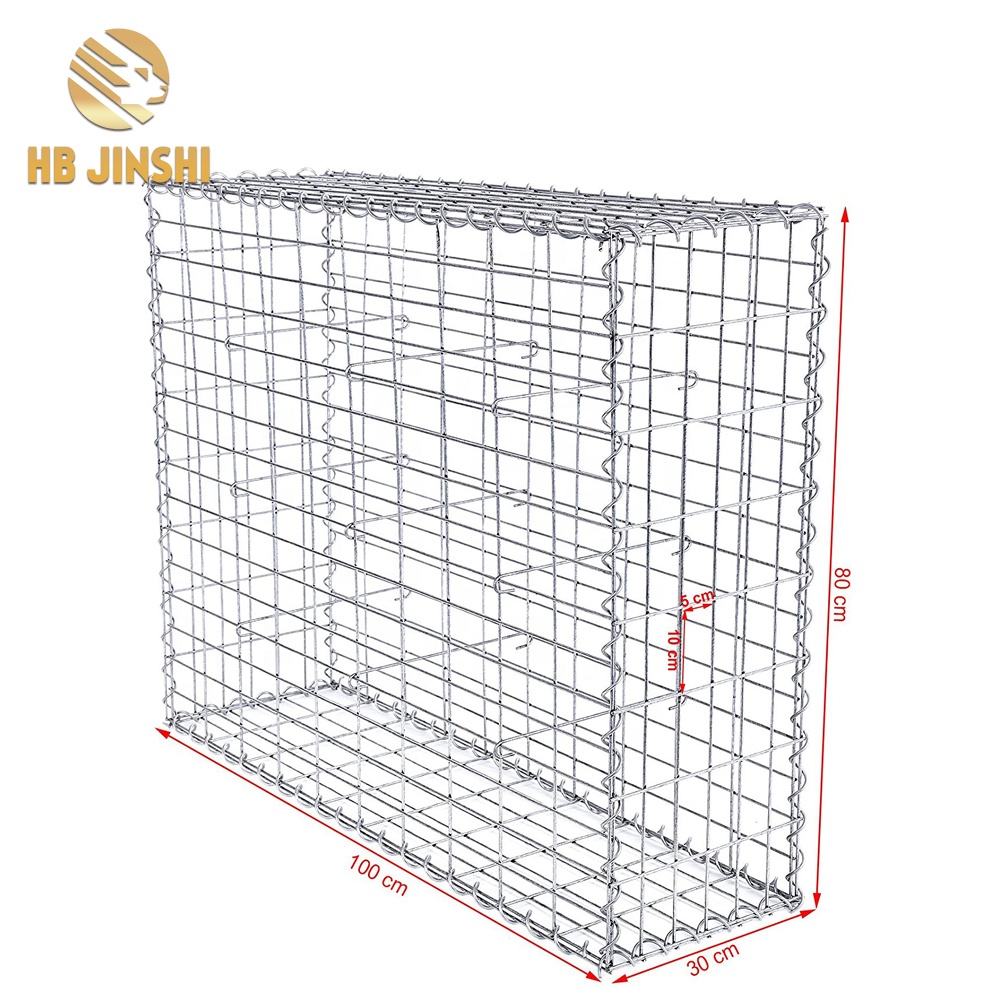

- Size of per piece:

-

1x1x1m,1x2x1m,1×0.5x2m,1x1x3m etc

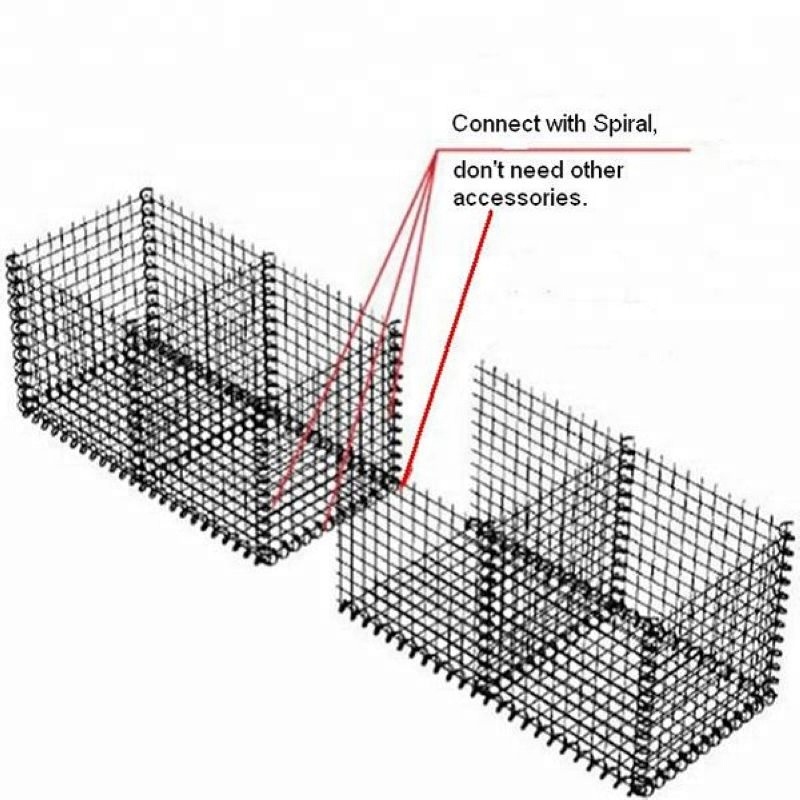

- Connection type:

-

welded,then Connected by Spiral Wire

- Usage:

-

garden,road,gym fence,egg basket,filter

- Certification:

-

ISO , CE, SGS

Packaging & Delivery

- Selling Units:

- Single item

- Single package size:

- 100X50X50 cm

- Single gross weight:

- 10.900 kg

- Package Type:

- 1. on pallet2. mail order packing

- Picture Example:

-

- Lead Time :

-

Quantity(Sets) 1 – 500 501 – 1500 1501 – 3500 >3500 Est. Time(days) 15 25 40 To be negotiated

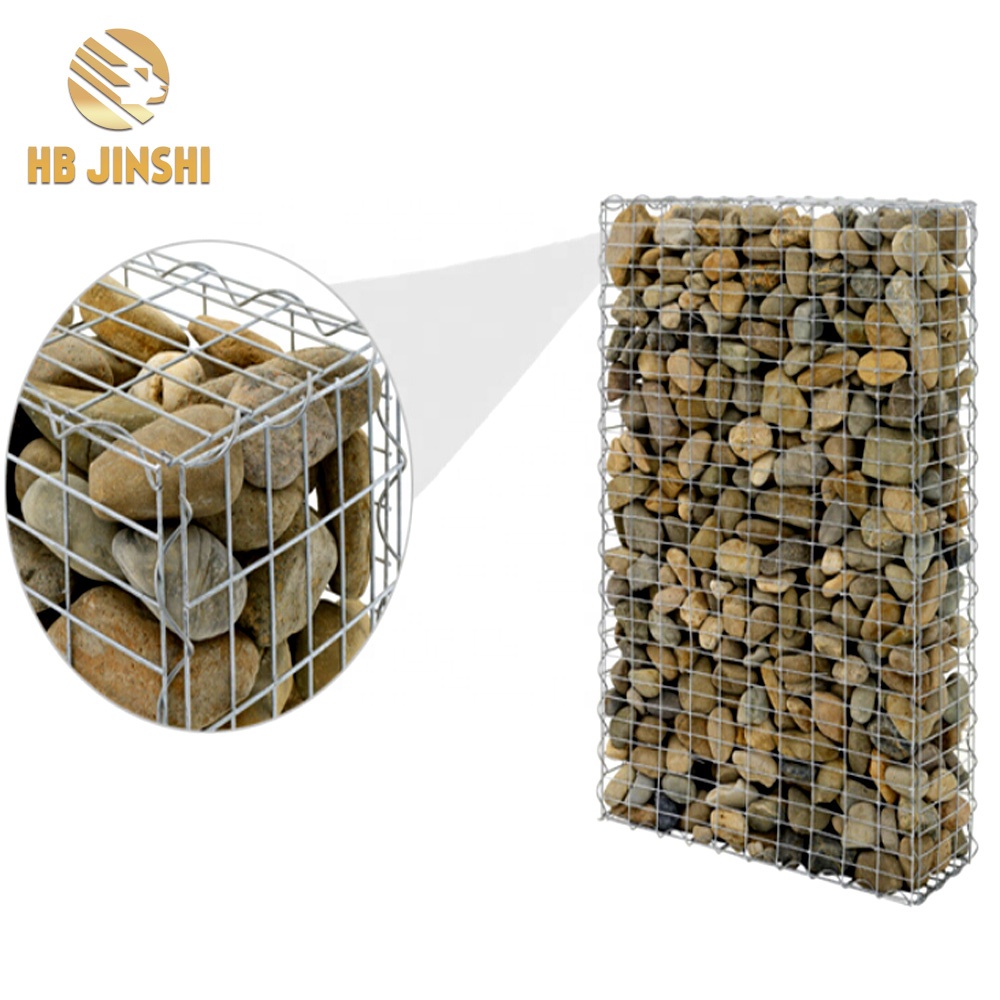

Welded Gabion, Gabion Box

Specifications

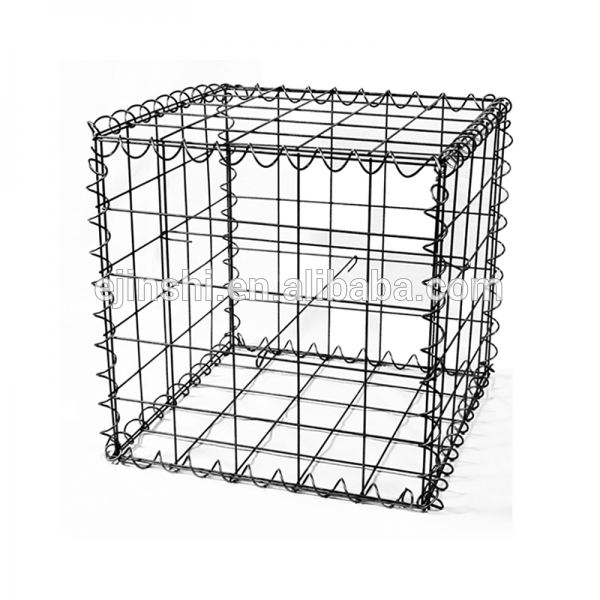

1. Welded Box

1.)Material: Galvanized Iron Wire

2.)Hole Shape: Square

3)Mesh Wire Gl. Dia.:2.0-4.0mm

4.)Aperture: 60*80mm,80*100mm,100*120mm

5.)Standard Mesh:60x80mm-120x150mm

2.Welded Gabion Description:

Welded Gabion is manufactured from cold drawn steel wire and strictly conform toBS1052:1986 for tensile strength. It is then electrically welded together and Hot Dip Galvanised or Alu-Zinc coated to BS443/EN10244-2, ensuring a longer life. The meshes can then be organic polymer coated to safeguard against corrosion and other weathering effects, especially when the are to be used in salty and highly polluted environments. Our Gabion Box is coated using the Galfan process.

Materials applied for Welded Gabion are galvanized iron, stainless steel, plastic coated iron wire or even brass wire.

• galvanized after welded ,galvanized before welded ,

• PVC coated galvanized

• hot-dipped galvanized

• electro galvanized

3. Welded Gabion Specification:

|

Normal Box sizes (m)

|

NO. of diaphragms (pcs)

|

Capacity ( m 3)

|

|

0.5 x 0.5 x 0.5

|

0

|

0.125

|

|

1 x 0.5 x 0.5

|

0

|

0.25

|

|

1 x 1 x 0.5

|

0

|

0.5

|

|

1 x 1 x 1

|

0

|

1

|

|

1.5 x 0.5 x 0.5

|

0

|

0.325

|

|

1.5 x 1 x 0.5

|

0

|

0.75

|

|

1.5 x 1 x 1

|

0

|

1.5

|

|

2 x 0.5 x 0.5

|

1

|

0.5

|

|

2 x 1 x 0.5

|

1

|

1

|

|

2 x 1 x 1

|

1

|

2

|

|

This table refers to the industry standard unit sizes; non-standard unit sizes are available in dimensions of multiples of the mesh opening

|

||

|

Corrosion Protection |

Galvanized |

95% Zinc + 5% Alu |

PVC Coated |

|

Mesh Size |

50.8 x 50.8mm 76.2 x76.2mm |

50.8 x 50.8mm 76.2 x76.2mm |

50.8 x 50.8mm 76.2 x76.2mm |

|

Unite Size |

Wire Diameter |

Wire Diameter |

Wire Diameter |

|

1 x 1 x 1m |

3.0mm,4.0mm,5.0mm |

3.0mm,4.0mm,5.0mm |

3.0mm/3.8mm |

|

2 x 1x 1m |

3.0mm,4.0mm,5.0mm |

3.0mm,4.0mm,5.0mm |

3.0mm/3.8mm |

|

3x 1 x 1m |

3.0mm,4.0mm,5.0mm |

3.0mm,4.0mm,5.0mm |

3.0mm/3.8mm |

|

4 x 1 x 1m |

3.0mm,4.0mm,5.0mm |

3.0mm,4.0mm,5.0mm |

3.0mm/3.8mm |

|

1 x 1 x 0.5m |

3.0mm,4.0mm,5.0mm |

3.0mm,4.0mm,5.0mm |

3.0mm/3.8mm |

|

2 x 1x 0.5m |

3.0mm,4.0mm,5.0mm |

3.0mm,4.0mm,5.0mm |

3.0mm/3.8mm |

|

3x 1 x 0.5m |

3.0mm,4.0mm,5.0mm |

3.0mm,4.0mm,5.0mm |

3.0mm/3.8mm |

|

4 x 1 x 0.5m |

3.0mm,4.0mm,5.0mm |

3.0mm,4.0mm,5.0mm |

3.0mm/3.8mm |

4.Easy to install Welded Gabion

Field installation is quick and easy. In fact, installation time can be as much as 40% less than required by hex type gabions. With diaphragms and stiffeners installed,the gabion box may be filled with standard loading equipment.After filling the gabion box, a lid is placed on top and secured with spiral binders,lacing wire or “C” rings.

Unlike hexagonal units,Gabion box hold their shape better – they don’t bulge out when filled .They are easy to handle,which means more work,less labor and highter productivity an the job.

Welded Gabion is made by one of the nation’s leading manufacturers of welded wire mesh. Each gabion box is constructed of rugged hight tensile wire which is coated with a thick, cor-rosion-resistant layer of zinc. The wire is also available with a tough,durable PVC coating. The jality materials results in a longer,gabion life. Jinshi welded wire supplied from stock in a complete Custom sizes to fit unique site con-ailable on special order.

5.The Advantages of Welded Gabion

1.)Flexible

Superior to rigid type structures. The Gabion box construction permits natural adjustment to varying conditions of earth settlement without causing fracture or collapse of the structure.

2.)Durable

Gaps between the stones silt up naturally as time passes. Silting supports the growth of grass and plants which serve as a bonding agent for the stone.

3.)Permeable

A Welded Gabion structure allows water to pass through, water pressure cannot build up behind it and the structure is continuously drained.

4.)Strong

The flexibility of the Gabion box structure provides the inherent strength to withstand and dissipate pressures exerted by water and earth masses.

5.)Economical

Filling materials are usually found on or near the site. No structural maintenance is needed and foundation work is usually unnecessary.

6.)Natural Appearance

Natural stone makes the structure aesthetically pleasing especially when subsequent vegetation growth takes place.

7.)Simple

Unskilled labour can be used for quick assembly.

8.)Maintenance

Gabion box structures are easily maintained using additional mesh or grouting.

9.)Extendable

Extensions are simple. Additional units are simply attached to the existing ones.

6.Application of Welded Gabion:

Welded gabion box is widely used for the control and guide of water; preventing of rock breaking; water and soil, roadway and bridge protection; strengthening structure of soil; protection engineering of seaside area and retaining wall structures; hydraulic structures, dams and culverts; coastal embankment works; architectural feature retaining walls.The main application as follows:

1.)Flood discharge and lead flow

2.)Rock fall defending

3.)Preventing the water and soil lost

4.)Protecting the bridge

5.)Reinforce fabric

6.)Seashore recovery project

7.)Seaport project

8.)Block gabion wall

9.)Defending the road

Packaging of Welded Gabion:

1. Can you offer free sample?

Hebei Jinshi can offer you high quality free sample

2. Are you a manufacturer?

Yes, we have been in providing the professional products in fence field for 17 years.

3. Can I customize the products?

Yes, as long as provide specifications, drawings can only do what you want products.

4.How about the delivery time?

Usually within 15-20 days , customized order may need longer time.

5. How about the payment terms?

T/T (with 30% deposit), L/C at sight. Western Union.

Any questions, please feel free to contact us. We will reply to you within 8 hours. Thank you!